Just How CNC Machining Solutions Improve Efficiency in Milling and Turning Procedures

CNC machining solutions play a crucial role in improving performance within milling and transforming processes. By making use of automation and exact control, these solutions lessen human mistake and assurance consistent output. The capability to deal with intricate geometries and keep limited tolerances enhances manufacturing. The full extent of CNC technology's effect goes beyond standard efficiency gains. There are much deeper ramifications and future trends that warrant more exploration.

The Fundamentals of CNC Machining

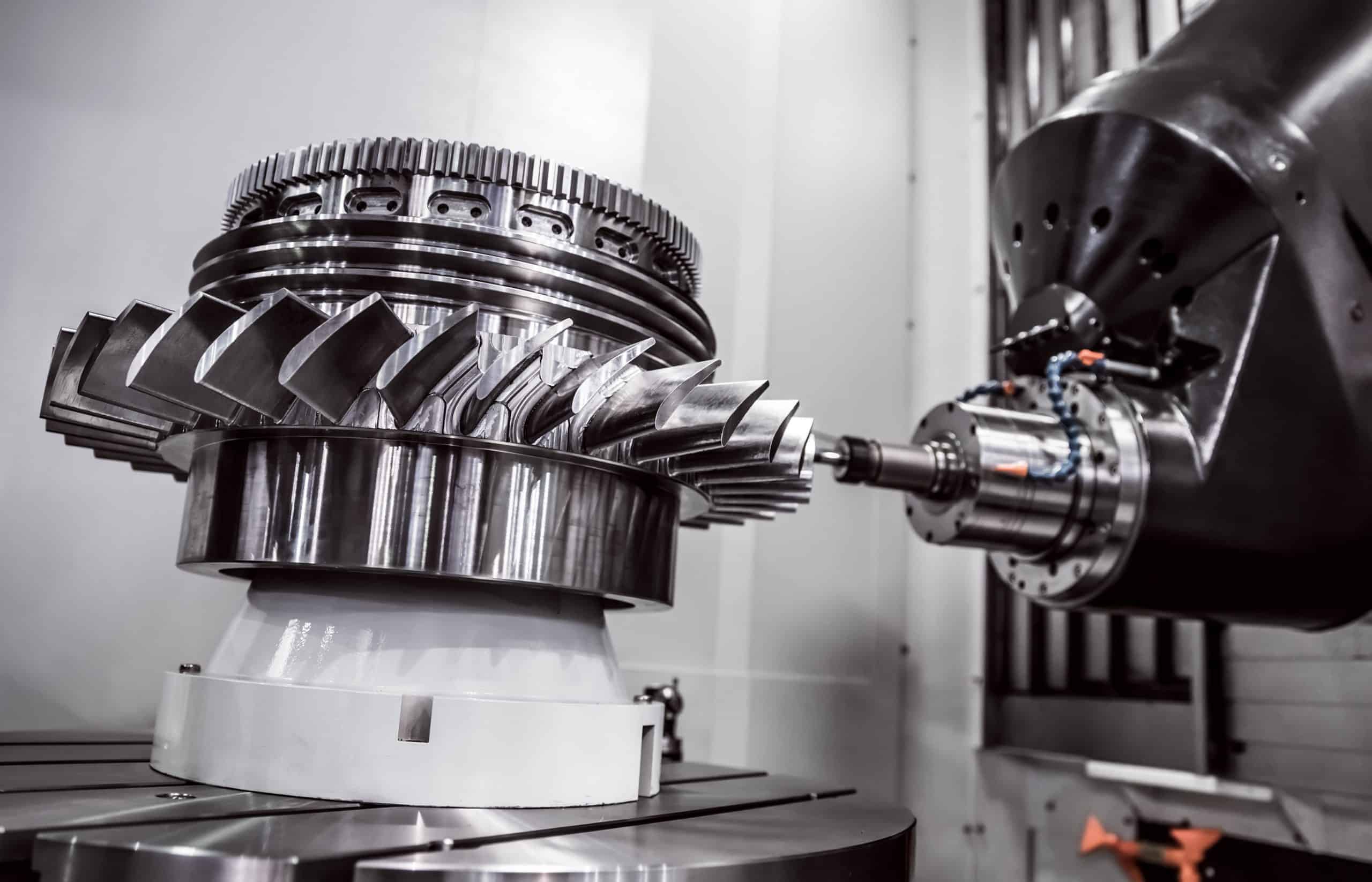

CNC machining is a specific production process that uses computer-controlled equipments to produce elaborate components and components. This technology uses computer-aided style (CAD) software application to develop thorough designs, which are then converted into maker instructions. The procedure normally includes numerous procedures such as milling, turning, and drilling, making it possible for makers to achieve high degrees of precision and repeatability.

CNC equipments are equipped with sophisticated tooling that can manipulate products like steel, wood, and plastic. They operate with a series of commands that determine movements, speeds, and device modifications, reducing human mistake and enhancing production performance.

The automation integral in CNC machining permits limited tolerances and complex geometries to be consistently created, making it a preferred option in markets calling for precision, such as aerospace and automobile. Comprehending the fundamentals of CNC machining is important for valuing its role in contemporary manufacturing procedures.

Benefits of CNC Machining in Milling

CNC machining uses significant advantages in milling processes, specifically concerning precision and precision. This innovation not just boosts production rate but additionally enables for the production of complex layouts that would be challenging to attain manually. Consequently, companies can boost performance and expand their abilities in production.

Precision and Accuracy

Achieving unparalleled accuracy and precision in milling procedures is a characteristic of innovative machining methods. CNC machining solutions use computer-controlled systems that carefully carry out styles with very little human intervention. This automation ensures that each cut and contour is executed to precise specifications, significantly minimizing the risk of errors usually related to hand-operated milling. The capability to produce elaborate geometries with tight tolerances is a crucial advantage, allowing manufacturers to fulfill rigorous high quality requirements. In addition, CNC equipments can maintain constant performance throughout numerous runs, ensuring harmony in production. This level of accuracy not just boosts item top quality yet also decreases product waste, bring about extra effective use of sources. Generally, CNC machining services change milling procedures with their commitment to precision and information.

Boosted Manufacturing Speed

Increasing production rate is one of the standout advantages of contemporary machining solutions. CNC machining considerably reduces the moment needed for milling procedures by automating operations and lessening hand-operated treatment. Equipments can run constantly, permitting for raised outcome without compromising quality. The capability to program several tasks into a solitary setup better enhances production, allowing suppliers to full facility work in much less time. Additionally, CNC makers keep high-speed cutting capacities, resulting in quicker material elimination and faster cycle times. This enhanced effectiveness translates to much shorter preparations, enabling companies to react quickly to market needs. Generally, boosted production rate through CNC machining not just increases efficiency yet additionally improves competitive advantage in the production market.

Facility Layout Abilities

The capability to develop detailed layouts is a significant benefit of modern-day machining services. CNC machining enables the manufacturing of complicated geometries that would be tough, if not impossible, to achieve utilizing typical techniques. This capacity stems from sophisticated programs and automated devices that specifically adhere to digital plans, making certain accuracy and repeatability. Consequently, makers can create elaborate get rid of limited resistances, maximizing performance in various applications. Furthermore, the adaptability of CNC equipments allows quick modifications to develop specs without substantial retooling, simplifying the production process. This versatility not just enhances imagination in layout but likewise allows for efficient testing and advancement, offering companies an one-upmanship in the ever-evolving market.

Advantages of CNC Transforming Procedures

CNC transforming processes supply substantial advantages in production, particularly relating to accuracy and precision. These procedures enable the development of highly described components with very little resistances, guaranteeing quality in manufacturing. Furthermore, the performance of CNC transforming adds to reduced preparations, enabling quicker delivery of completed products.

Precision and Accuracy

Precision and accuracy are trademark features of CNC turning procedures, establishing them apart in the manufacturing landscape. These processes utilize computer system numerical control to guide cutting tools with unparalleled exactness. This causes elements that meet stringent requirements and tolerances, decreasing the likelihood of mistakes. CNC turning enables repeatable and constant manufacturing, making sure that each part is virtually similar, which is vital in industries calling for high requirements, such as aerospace and clinical tools - tool and die maker. Additionally, advanced software application and innovation enable real-time adjustments throughout machining, enhancing total high quality. By lessening human error and optimizing control over the manufacturing process, CNC turning services supply premium accuracy and accuracy, making them a crucial choice for contemporary production requirements

Minimized Lead Times

Minimized preparations are a considerable benefit of CNC transforming processes, coming from their capacity to automate and optimize production. CNC turning equipments run with high performance, permitting rapid arrangement and execution of several jobs without the demand for comprehensive manual intervention. This automation minimizes downtime and accelerates the production procedure, allowing quicker turnaround for orders. In addition, CNC innovation enhances uniformity and minimizes errors, which additionally adds to faster manufacturing cycles. Consequently, companies can meet limited due dates and respond without delay to market demands. By leveraging CNC transforming procedures, business like it can enhance process, boost resource allotment, and eventually boost their competitive side with decreased lead times.

Precision and Accuracy in Manufacturing

While making processes have actually developed considerably throughout the years, the relevance of precision and accuracy continues to be extremely important. In CNC machining, these two aspects are critical to creating high-grade elements that meet precise requirements. The assimilation of advanced computer system modern technology enables thorough control over machining parameters, ensuring that components are crafted with very little variance from intended designs.

Accuracy in making describes the repeatability of procedures, while precision denotes how closely a completed component aligns with its intended measurements. CNC devices make use of sophisticated software application and devices that make it possible for suppliers to achieve both, noticeably decreasing the margin for error - fast prototyping. This capacity is particularly necessary in sectors such as aerospace, automotive, and medical, where even small mistakes can cause devastating failures

Lowering Lead Times With CNC Modern Technology

CNC technology accelerates manufacturing timelines by simplifying the machining procedure. By automating tasks, CNC visit devices reduce hand-operated intervention, significantly lowering the time needed for setup and procedure. This effectiveness enables manufacturers to react quickly to market needs, satisfying orders much faster than traditional machining methods allow.

Additionally, CNC modern technology provides fast prototyping capacities, enabling for quick versions and changes based on customer responses. The accuracy of CNC machining makes certain that parts are created appropriately the first time, lowering the chance of costly errors and revamp.

In addition, advanced organizing and shows capabilities optimize workflow, enabling several operations to run simultaneously. This assimilation of modern technology not just shortens preparations however also enhances total productivity. Ultimately, the fostering of CNC machining solutions outfits manufacturers with the tools necessary to satisfy limited due dates while preserving top notch standards in manufacturing.

The Future of CNC Machining in Market

As suppliers increasingly adopt CNC innovation to enhance procedures and minimize lead times, the future of CNC machining in sector appears Recommended Site promising. Developments such as fabricated knowledge and machine discovering are readied to revolutionize the capacities of CNC machines, boosting their accuracy and flexibility. These innovations will certainly help with real-time tracking and predictive upkeep, minimizing downtime and maximizing production effectiveness.

The integration of Web of Things (IoT) technologies will certainly allow much better data collection and evaluation, permitting makers to make informed decisions that further improve functional efficiency. The increase of additive production together with CNC machining is expected to complement traditional approaches, supplying higher layout flexibility and material performance.

Additionally, as sustainability comes to be a top priority, CNC machining is developing to integrate eco-friendly techniques, which will draw in environmentally mindful consumers. Overall, the future of CNC machining is defined by continuous technology and adjustment, placing it as a cornerstone of modern-day manufacturing.

Regularly Asked Questions

What Products Work With CNC Machining Services?

CNC machining services are compatible with different materials, consisting of metals like steel, aluminum, and titanium, in addition to plastics such as acrylic and polycarbonate. Timber and compounds likewise suit CNC processes for diverse applications.

Exactly How Does CNC Machining Contrast to Conventional Machining Methods?

CNC machining uses greater uniformity, automation, and accuracy contrasted to conventional approaches. It lowers human mistake, enhances manufacturing rate, and allows for complex designs, making it a superior selection in contemporary manufacturing settings.

What Industries Advantage one of the most From CNC Machining Services?

The aerospace, automobile, clinical, and electronic devices markets profit substantially from CNC machining services. These sectors leverage speed, accuracy, and personalization to improve product quality while reducing production prices and time, eventually enhancing general functional efficiency.

Can CNC Machines Deal With Complicated Geometries and Designs?

CNC equipments are proficient at handling intricate geometries and layouts, permitting precision and elaborate describing. Their sophisticated shows capacities enable producers to create parts with high accuracy, conference varied industry needs and enhancing product functionality.

What Is the Common Cost Range for CNC Machining Solutions?

The typical expense array for CNC machining services varies commonly, generally falling in between $50 to $150 per hour, relying on aspects such as product, complexity, quantity, and the specific machining processes employed.

CNC machining is a precise manufacturing process that makes use of computer-controlled machines to generate detailed parts and elements. CNC machining uses considerable advantages in milling procedures, especially regarding precision and precision. CNC machining greatly lowers the time needed for crushing procedures by automating operations and minimizing hand-operated treatment. CNC technology increases production timelines by enhancing the machining procedure. As producers increasingly take on CNC technology to simplify procedures and minimize lead times, the future of CNC machining in sector appears appealing.